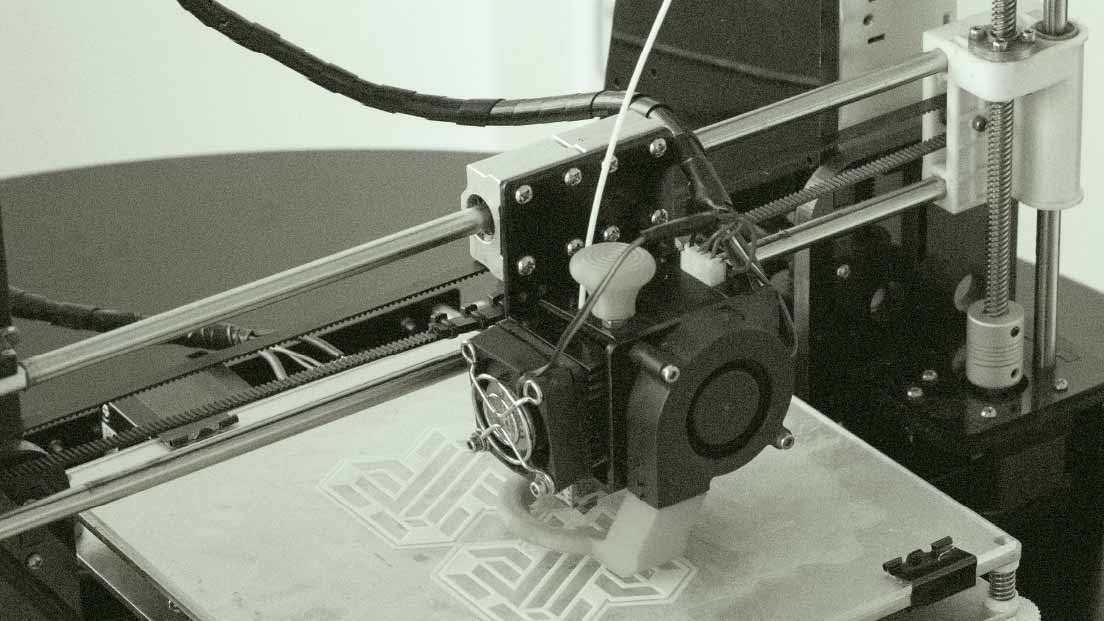

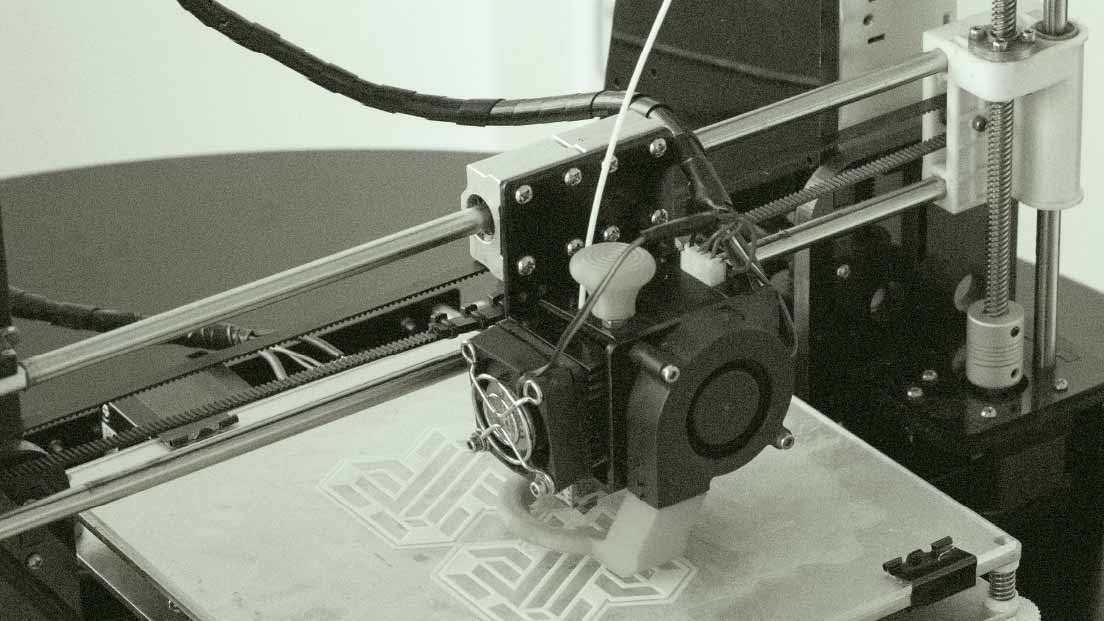

3D PRINTING

The rapid prototyping service using 3D printing further enhances the design activity, especially in those situations where the creation of "full custom" solutions is required. Indeed, rapid prototyping allows for dimensional and functional testing of the result of the design activity. Of high potential is then the possibility of integrating this technology with numerical fluid dynamics (CFD) simulation, realizing a link between theoretical modeling and experimental testing.

The advantages of3D printing

Through the 3D printing service it is possible to create multiple prototypes of a component even in very complex shapes and in a wide range of materials.

1. Mockups

Construction of a threedimensional model of high degree of precision.

2. Encumbrances

Realistic simulation of the proportions between the different elements and spaces.

3. Final results

Detailed presentation of the final result of the design activity.

4. Functional prototypes

Creation of components with the aim of testing their functionality, individually or as part of complex assemblies.